Benefits of a Concrete Block Machine

In an era where construction speed, structural integrity, and cost-efficiency are more important than ever, the concrete block making machine has become a must-have for builders worldwide. Whether you’re running a small manufacturing site or handling large-scale projects, investing in a block making machine can transform your operations from labor-intensive to fully automated—and from inconsistent to industrially precise.

So, what are the real benefits of using a concrete block machine? Let’s explore how it can improve your production capacity and bottom line.

Higher Output, Faster Construction

Speed is the essence of construction activities. An up-to-date concrete blocks production unit can generate anything from hundreds to thousands of blocks per hour, provided the type of machine is known. This substantially shortens the time required to finish projects within the schedule and makes it easy for contractors to expand their activities without reducing quality.

Highly-efficient KBL Machinery lines, which are quite appropriate for shaping the production patterns of the market, are comprised of automation with hydraulic pressing and the system of automatic pallets.

Uniform Quality, Every Block

When blocks are made by hand the dimensions are often irregular and the density can vary. As a result, not only is the building less strong but also the energy required to refill the blocks.

On the contrary, a cement block making machine forces each block to be uniformly hard through the coordinated movements of the press plates resulting in a perfect piece with respect to both its strength and visual features.

KBL Machinery’s equipment has moulds with high accuracy and latest vibration technology to provide a perfect product at each cycle.

Reduced Labor Costs

The pressure of the workers and the increasing salaries could dramatically influence the business state. When you’ve automated your block production process, you’re less reliant on manual labor and you also make human error less likely.

KBL’s block making machines are crafted such that they are easy to operate and also come with control panels that are intuitive and can still be used effectively with a comparatively smaller workforce.

Multi-functional Production Capabilities

One machine, many possibilities. A typical block making machine can produce:

- Hollow blocks

- Solid blocks

- Paving stones

- Interlocking bricks

With interchangeable mold systems, you can switch between products based on market needs—all using the same base machine. KBL Machinery supports custom mold designs to fit regional or client-specific requirements.

Sustainable & Cost-Effective Construction

Using a cement block making machine not only saves money but also supports eco-conscious building. These machines enable the use of recycled materials like fly ash, slag, and crushed stone in the block-making mix. This reduces environmental impact while lowering input costs.

KBL’s machines are optimized for minimal waste, low energy consumption, and maximum material utilization—making them a perfect choice for green building initiatives.

Long-Term ROI

Though the upfront investment in a concrete block machine might seem significant, the long-term returns are undeniable:

- Lower production costs

- Higher output

- Less material waste

- Fewer labor expenses

- Faster project turnaround

With proper maintenance, KBL Machinery equipment can operate reliably for many years, delivering a strong return on investment.

Global Support and Easy Maintenance

KBL Machinery stands out not only for the performance of its machines but also for its global customer service. From installation guidance and training to spare parts and remote diagnostics, KBL ensures your equipment runs smoothly and efficiently.

Customers in Asia, Africa, and the Middle East have praised KBL for responsive after-sales support and detailed user manuals in multiple languages.

Ready to Build Smarter?

Choosing a concrete block making machine isn’t just about producing blocks—it’s about upgrading your business model. With the help of KBL Machinery, companies worldwide are building smarter, faster, and more sustainably than ever before.

Whether you’re producing 5,000 blocks a day or aiming for 50,000, the right machine is your foundation for success.

Why KBL Machinery’s Brick Machines & Cement Block Making Machines Stand Out

When it comes to brick machines and cement block making machines, not all manufacturers deliver the same level of performance, durability, and innovation. KBL Machinery (Quanzhou Kimberly Machinery Manufacturing Co. Ltd) has been a trusted name in the industry for nearly 30 years, specializing in high-efficiency block production solutions.

Advanced Technology for Superior Performance

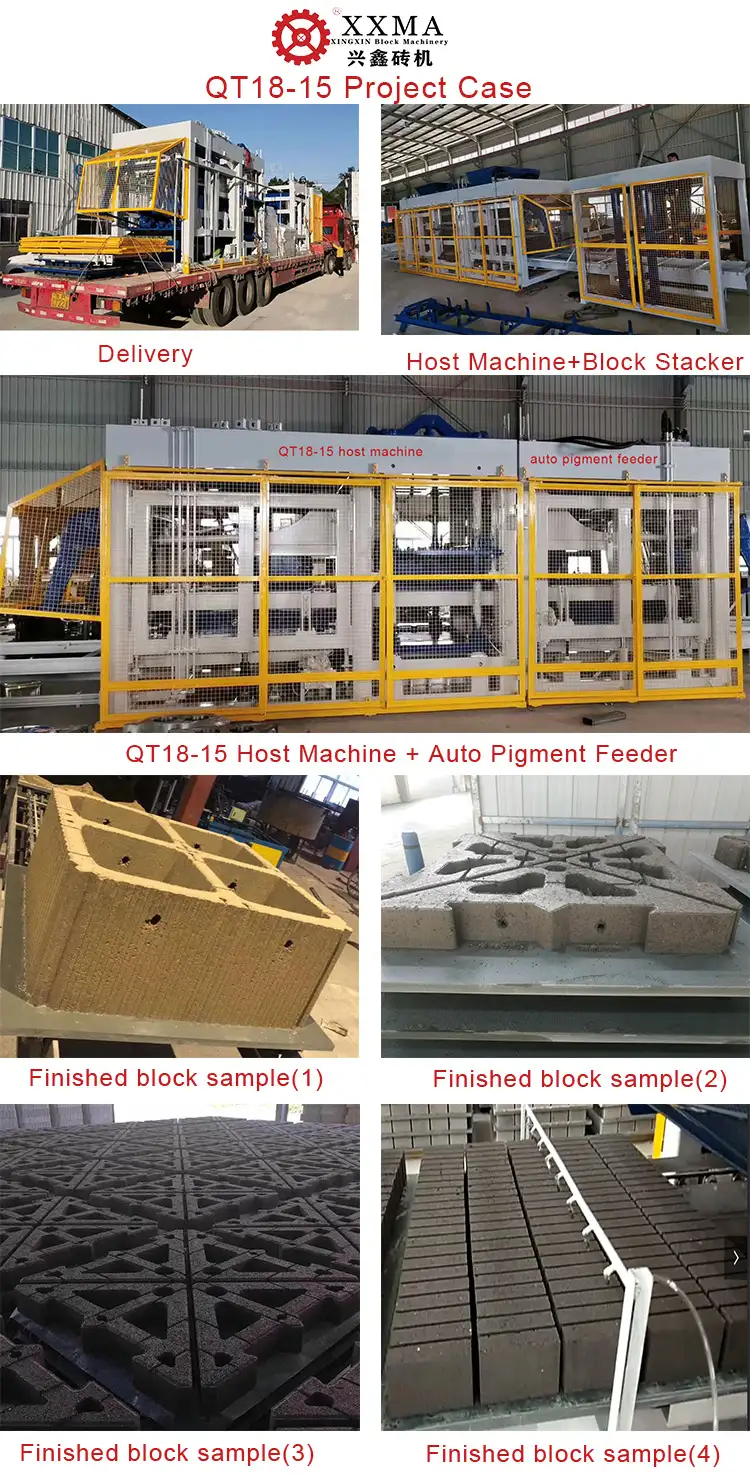

KBL’s QT series fully automatic concrete block machines and static hydraulic press series are engineered for maximum productivity and precision. Whether you need a machine for small-scale operations or a high-capacity brick machine for industrial projects, KBL offers models like:

- QT4-15 to QT18-15 (varying output capacities)

- Static press series (500T, 1200T, 1300T, etc.)

| lock sample name | Specification | Pcs/mold | Pcs/8hours |

|---|---|---|---|

| Hollow block | 390*190*190mm | 18pcs/mould | 27000-36000pcs/8 hours |

| Porous block | 240*115*90mm | 54pcs/mould | 65000-81000pcs/8 hours |

| Color paver | 200*100*60mm | 66pcs/mould | 66000-79200pcs/8 hours |

| Solid brick | 238*115*51mm | 110pcs/mould | 165000-198000pcs/8 hours |

These machines incorporate cutting-edge features, such as:

✔ German Frequency Conversion Control Technology – Ensures optimal vibration for uniform block density.

✔ YUKEN Hydraulic System (Taiwan Brand) – Fully sealed to prevent leaks, enhancing durability.

✔ High-Quality Molds (Q345B Steel, Heat-Treated) – CNC-cut for precision, ensuring longer lifespan.

✔ PLC Control (SIEMENS, ABB, Schneider Components) – Boosts efficiency with faster cycle times (as quick as 12-13 seconds per pallet for solid blocks).

Complete Production Line Solutions

KBL doesn’t just provide standalone machines—they offer fully integrated block production systems, including:

- Concrete mixers & batching machines

- Block palletizing cubers & soaking machines

- Auto pallet feeders & brick packing machines

- High-quality GMT Fiber & PVC Pallets

This end-to-end support ensures seamless operations, reducing downtime and maximizing output.

Built for Longevity & Easy Maintenance

Unlike low-cost alternatives, KBL’s brick machines and cement block making machines are built with heavy-duty materials, including one-piece casting vibration plates (no welding) for enhanced durability. Additionally, their global after-sales service ensures:

- Quick spare parts supply

- Multilingual technical support

- Remote troubleshooting & maintenance guidance

Sustainability & Cost Efficiency

KBL’s machines support eco-friendly construction by allowing the use of recycled materials (fly ash, slag, crushed stone) in block production. This not only reduces material costs but also minimizes environmental impact.

Proven Success Worldwide

From Asia and Africa to the Middle East, contractors and manufacturers trust KBL Machinery for:

- Higher daily output (up to 50,000+ blocks)

- Lower labor & operational costs

- Consistent, high-strength blocks

- 24/7 operation capability

Upgrade Your Production with KBL Today!

Whether you’re investing in your first brick machine or upgrading to a fully automated cement block making machine, KBL Machinery provides the technology, reliability, and support to keep your business competitive.

Contact KBL now to find the perfect block production solution for your needs!